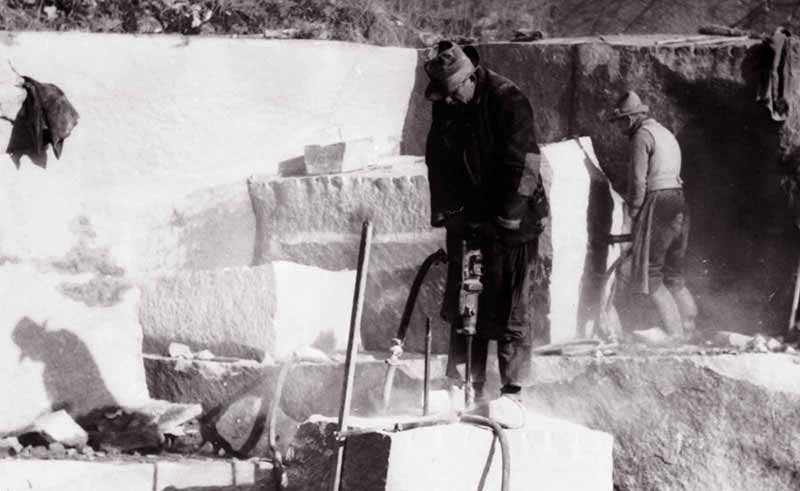

The large machine in front of you is a compressor unit that produces compressed air using an electric motor. This compressed air was needed in the quarries to operate pneumatic tools. Not long after the Second World War, the old world of quarrymen came to an end, particularly with the use of pneumatic hammers.

Pneumatic tools accelerated the work, but made the quarries loud. Hearing protection was needed, and it was no longer possible to talk while working. Then there were the dangerously fine stone dust particles and hammers’ vibration. This resulted in dust-filled lungs, damaged spinal discs and joints, as well as hearing and eye damage.

Silicosis or “dust lung,” in particular, is a typical stonemason’s disease. An X-ray of a severely affected lung can be seen on the quarry wall. Those affected by this disease suffer from shortness of breath and asthma and have a high risk of developing tuberculosis or lung cancer. There is also no known cure for this recognized occupational disease.

In addition to the use of pneumatic tools, motorization also changed the work in the quarries. Self-propelled loading vehicles took over transportation and made the old cranes, the trolleys and their tracks superfluous.

Stone processing was revolutionized by the introduction of powerful machines such as stone saws and grinders. Productivity increased enormously but, at the same time, the number of jobs fell sharply.

This brings us to a central problem of the modern granite industry. You can hear more about this at the control panel in front of the large saw blade.