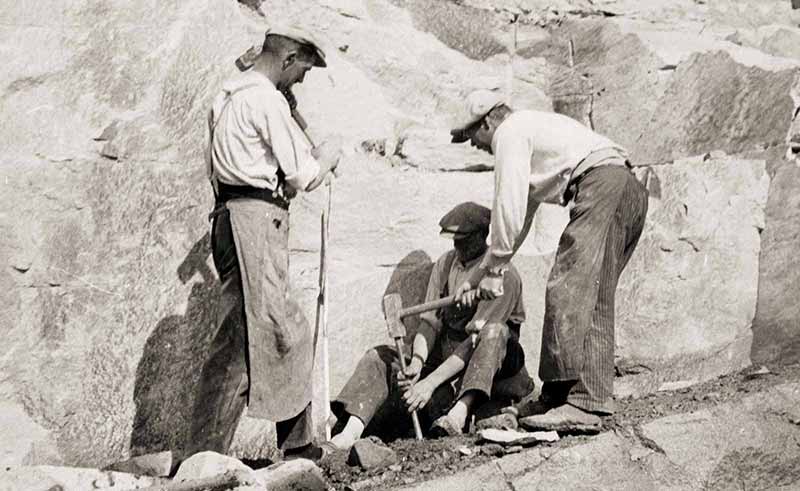

Extracting blocks from the rock face was difficult and dangerous work. In principle, the natural fissures were followed, which usually ran horizontally. However, there was no way to avoid the work of blasting with black powder. To do this, deep holes had to be painstakingly drilled. Three workers went to work drilling the holes. One held the drill rod, rotating it continuously while two men pounded the drill rod with heavy hammers. It took the three-man team nearly an hour to drill a hole 50 cm deep.

Once a block had been removed from the wall, it was divided further as needed. For this, wedge holes were pounded into the granite, and steel wedges were then driven into these until the granite “opened up,” or split.

The raw blocks that were finally produced, which usually weighed several tons, had to be transported to the work sheds for processing. Jib cranes and trolleys running on rails were used for this purpose.

Take a closer look at the wooden crane. Its load was suspended from a swiveling boom. The steel suspension cable was moved by turning a crank winch. This was how the blocks were lifted and swiveled, but the load could also be pulled across the ground.

Work in the quarry was dangerous and claimed many lives. This quarry, where one worker was killed, proved no exception. The cross at the foot of the quarry face marks the exact spot where the victim died. The plaque by the lake in front provides more information.

Next, we’ll head to the workplaces of the stonemasons and pavers. At the corner where the two wooden sheds meet, you’ll hear from me again.